ULGW Applications Overview

SoniTech’s Ultrasonic Localized Guided ‘Wrap’ Wave (ULGW) pipe inspection service has taken a huge leap beyond the competition, offering the most efficient, comprehensive, and low-risk method to map the location and severity of all common internal pipe integrity issues in almost all accessible piping systems. This unbiased third-party data allows you to make fact-based decisions to develop the most efficient mitigation plan, saving valuable time, money, and resources.

Since system shutdown is not required and the method is safe around sensitive electronics and processes, valuable inventory, food, and people, ULGW is the preferred method for evaluating almost all system types, especially within mission critical facilities.

ULGW does require direct access to the outer pipe wall for inspection, so consult with one of our specialists for systems such as buried piping, pipes behind drywall, or piping otherwise not reasonably accessible. While most systems are tested without impacting operations, there is an upper temperature threshold for the equipment, requiring high temperature systems be temporarily shut down and cooled prior to evaluation.

Contact Us with any questions regarding the capabilities of ULGW, including the ability to evaluate any piping not referenced here.

Common Applications for ULGW

Comparison to Traditional Pipe System Inspection Methods

Most pipe systems today are evaluated through one of three antiquated methods: flow test, visual inspection, and water tests. While each of the “tried and true” methods possess certain benefits, all have shortcomings that can lead to misinformation and/or a false sense of security regarding system integrity.

Flow tests can be an acceptable and inexpensive first line of defense for evaluating systems that are suspected to be in good condition, but the test only represents water flow through the flow path, a relatively small portion of the system. They provide no information on pitting or trapped air/water, and the process introduces fresh oxygenated water into the system and increases the likelihood of unnecessarily trapping air or water in the system, creating a corrosion-friendly environment.

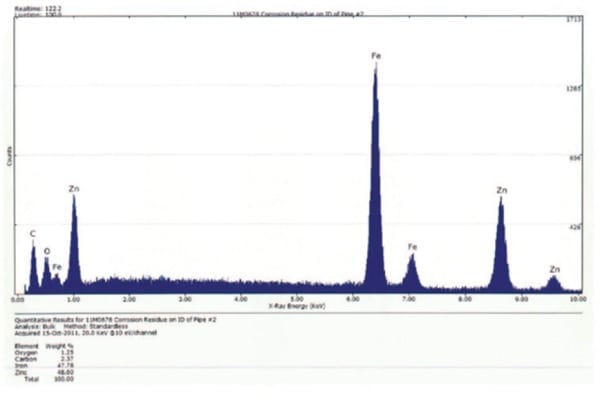

Internal visual inspection requires unnecessary system shutdown and risks associated with disassembly, and like a flow test, the data represents a very small percentage of the overall system condition. While visual inspection can show the degree of corrosion build-up if one knows where to look, it will not reveal pit depth below nodules or corrosive debris. Borescope is often used to extend the coverage of visual inspections, but the camera cannot protrude through multiple bends or small diameter piping, and the view is often obscured with “muddy water” or loose debris left in the pipe.

Watch the Borescope Sample Video.

Water tests and lab analysis may reveal the type of, or potential for, corrosive activity, but are very poor indicators of overall system health. Water tests could show “high levels” of the potential for MIC bacteria in the water, but that does not always mean there is corrosion present within the system nor does it pinpoint where that corrosion may exist. Lab analysis requires the same system shut down, risks, and limited data representation as associated with visual inspections. There is still a need to know where the corrosion is within the system to collect a useful sample, which is impossible without another type of evaluation method.

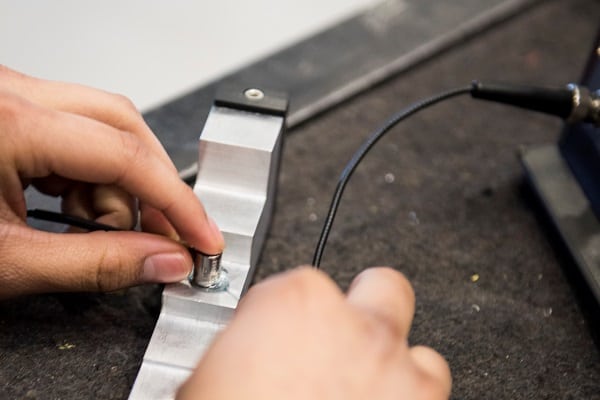

Ultrasonic thickness testing (UT) is also used to evaluate piping systems, but it is important not to confuse the capabilities of advanced ULGW with traditional UT. While ULGW can detect all common internal integrity issues (wall loss, corrosion and scale build up, trapped air and water, ice, etc.) around the entire circumference of the pipe, traditional UT can only detect remaining wall thickness (not corrosion buildup or any other anomaly) and the data only represents a pencil lead size area on the pipe.

While organizations like the National Fire Protection Association accept these investigation methods for pipe evaluation, merely meeting the minimum requirements is not likely sufficient to know the existence, location, and magnitude of internal issues, resulting in unnecessary repair costs and/or potential risks in relying on compromised system piping. The larger the system, the greater the chances of missing something important with these methods. While choosing a method to evaluate your pipe systems, it is important to understand your acceptable level of risk financially, with property loss, and life safety…particularly with critical systems such as fire suppression.

ULGW is the only method capable of locating the presence and severity of all common internal pipe integrity issues, without having to shut the system down and disassemble for inspection. More info can be found here.

Please Contact Us to learn more about SoniTech NDT’s capabilities and associated benefits of our non-destructive piping assessments